Vacuum pumps are essential tools in waste management, water treatment applications, and more. They are critical components in processes like sludge handling, dewatering, and chemical transfer, helping professionals enhance efficiency and reduce downtime.

However, purchasing the right vacuum pump for a specific task requires careful consideration. This guide walks you through the key questions to ask before making a decision to ensure you choose a pump that fits your operational requirements perfectly.

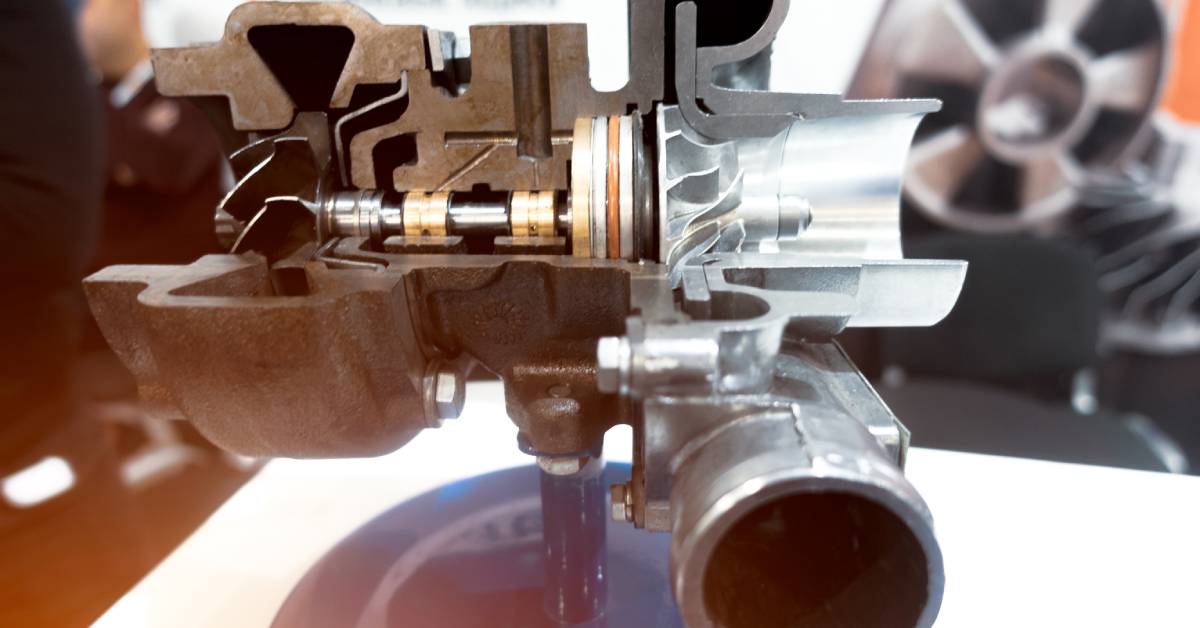

Vacuum pumps are specialized devices that remove air and other gases from a sealed environment, creating a vacuum. These tools are essential in a variety of industrial applications thanks to their ability to maintain controlled environments. They are most common in settings such as waste management facilities and septic applications, where precise and efficient operations are crucial.

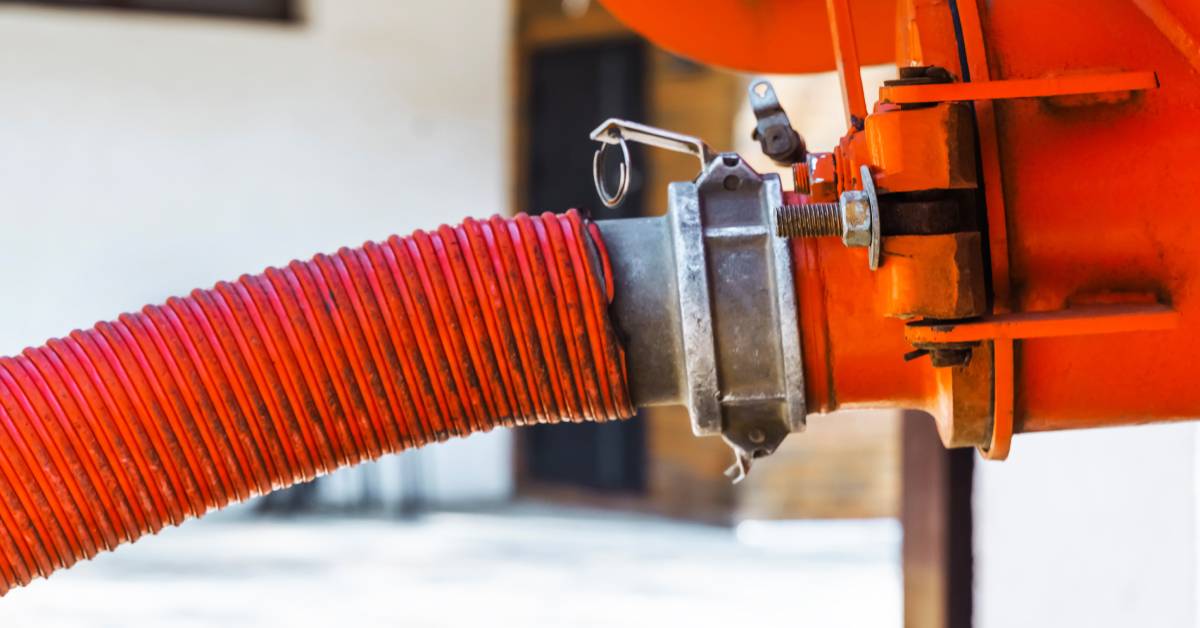

Vacuum pumps handle liquid waste and manage slurries, operating effectively in pressure-intensive circumstances. This makes them indispensable for these industries. Additionally, they enable processes like degassing, drying, and filtration, where maintaining a vacuum is essential for optimal results.

The reliability and performance of a vacuum pump can significantly impact the overall productivity and efficiency of your equipment or plant, making it critical to carefully select the right model for your specific needs. Choosing the appropriate pump ensures smoother operations and helps reduce maintenance costs and downtime, contributing to long-term success.

The first consideration is the type of material the pump will need to move. Waste professionals often deal with sludge, wastewater, or chemical-laden liquids, while water treatment facilities may work with clean or contaminated water.

The material properties, like viscosity, corrosiveness, and particulate content, dictate the type of pump you’ll need. For example, abrasive materials will require pumps designed for high durability and wear resistance, while corrosive liquids will demand corrosion-resistant materials.

Once you know what material you need to pump, examine the types of compatible materials. The pump’s material construction should align with the characteristics of the material it will handle.

Common material options include stainless steel for corrosive applications, cast iron for durability, and plastic for lightweight and non-corrosive needs. Selecting the right material ensures the pump withstands operational conditions, extending its lifespan and lowering maintenance costs. Failure to choose compatible materials could lead to frequent breakdowns, higher long-term expenses, or unsafe conditions.

Flow rate, which experts measure in gallons per minute (GPM) or liters per minute (LPM), represents the amount of material a vacuum pump can move within a specific period. It helps determine a pump’s suitability for a given application. To select the right pump, you need to calculate the required flow rate based on the volume of material you need to handle and the frequency at which the pump will operate.

For example, industrial applications such as large-scale waste management or heavy-duty liquid transfer often demand pumps with a high flow rate to handle significant volumes efficiently. Conversely, processes like small-scale water treatment or laboratory use may only require pumps with lower flow rates, as the material volume is relatively smaller.

By carefully considering your needs and choosing a pump with the appropriate flow rate, you can ensure smoother operations, improved efficiency, and a longer lifespan for your pump, while avoiding unnecessary strain or underperformance.

The vacuum level, which you’ll often find noted as millimeters of mercury (mmHg) or inches of mercury (inHg), refers to the pump’s capacity to create a vacuum by reducing pressure within a system. Different applications require varying vacuum levels to function effectively, so it’s key to understand the level required and choose a compatible pump.

For example, processes such as degassing liquids or materials often demand higher vacuum levels to remove trapped gases efficiently, while simpler tasks like fluid transfer may only require a moderate vacuum level. Using a pump that matches the operational requirements of your process ensures consistent performance and prevents overworking the pump, which can lead to unnecessary energy consumption and wear and tear over time. Understanding these specifications promotes optimal efficiency, prolongs the equipment’s lifespan, and can reduce operational costs.

Understanding the pump’s operational temperature range is essential for ensuring reliable and lasting performance. High temperatures can weaken the pump’s construction materials, degrade seals, and reduce the effectiveness of lubricants, which can lead to leaks or breakdowns.

On the other hand, low temperatures can impact the viscosity of process fluids, making them thicker and harder to pump, which can strain the system and reduce efficiency. Additionally, extreme cold can cause components to become brittle, increasing the risk of damage. To avoid performance issues or premature failures, thoroughly assess the expected operating temperature range of your application and confirm that the selected pump can function effectively under those conditions.

Budget constraints are always a critical consideration. Vacuum pumps come in a wide price range depending on the material, size, and features.

Consider the total cost of ownership, including maintenance, repair, and energy consumption. Investing in a higher-quality pump upfront can lead to long-term savings by minimizing operational downtimes and servicing expenses.

Any vacuum pump, regardless of its quality, will eventually require maintenance. Consider the availability of maintenance services for the model you’re purchasing.

Many local services offer reliable maintenance and support for a wide range of vacuum pumps, ensuring minimal downtime and optimal performance. Partnering with a supplier that provides repair services and replacement parts is crucial for maintaining the longevity of your pump.

Choosing the best vacuum pump involves finding a trusted supplier with an extensive range of options. Varco Supply specializes in delivering top-quality vacuum pumps for sale in a wide variety of materials, sizes, and specifications. Our inventory includes models suitable for a variety of applications, along with expert guidance to help you make the right choice.

The right vacuum pump will meet your operational requirements while offering durability and efficiency. Assess your needs by asking yourself these various questions before you buy your vacuum pump. Factor in ongoing maintenance and a reasonable budget to ensure the pump you select offers the best value for your investment.

Selecting the ideal vacuum pump is not just about capability—it’s about reliability, efficiency, and supporting your business objectives. Make an informed decision by partnering with a supplier like Varco Supply, who can guide you through the process and provide maintenance support for your vacuum pump’s long-term success.