Brass valves are essential components in fluid control systems, renowned for their durability, resistance to corrosion, and excellent sealing capabilities. They are widely used across various industries due to their ability to handle high pressures and temperatures. Brass valves, such as lever, piston, gate, and ball valves, provide precise control over fluid flow, ensuring efficient and reliable operation of systems. Their versatility and robust performance make them indispensable in maintaining the integrity and functionality of piping systems, preventing leaks, and ensuring safe and efficient fluid management. In this blog post, we will take a look at the types of brass valves offered at Varco, and discuss their applications and importance.

Brass lever valves are known for their straightforward operation and reliability. Featuring a lever handle, these valves enable quick and easy manual control to start or stop the flow of liquids with a simple 90-degree turn. The durability and corrosion resistance of brass make these valves ideal for various applications, including plumbing, water supply lines, fuel lines, and HVAC systems. Brass lever valves are particularly valued in settings requiring frequent and rapid operation, ensuring efficient and reliable flow control in both residential and industrial contexts. Their robust construction and ease of use make them vital for maintaining fluid system integrity and performance. Here at Varco, the lever valve is the most popular seller among the variety of brass valves that we offer.

Brass piston valves are prized for their precision and durability. These valves use a piston to regulate the flow of liquids, providing accurate control over pressure and flow rates. The robust nature of brass makes these valves highly resistant to wear and corrosion, making them ideal for high-pressure and high-temperature environments. Brass piston valves are commonly used in industrial applications such as steam systems, hydraulic systems, and chemical processing, where precise flow control is critical. Their ability to withstand harsh conditions while maintaining reliable performance makes brass piston valves indispensable in maintaining system efficiency and safety.

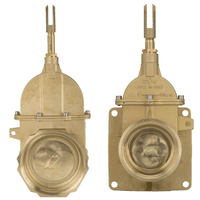

Gate valves provide unobstructed flow when fully open and a secure seal when closed. They operate by lifting a gate out of the fluid path, allowing for minimal pressure drop and efficient flow control. Due to their straightforward design and robust construction, gate valves are widely used in applications requiring infrequent operation, such as water supply systems, wastewater treatment, and oil and gas pipelines. They are particularly effective in situations where a straight-line flow of fluid and tight shutoff is necessary. The durability and reliability of gate valves make them a crucial component in maintaining the integrity and functionality of large-scale piping systems.

Ball valves are essential components in fluid control systems, known for their reliable performance and ease of operation. They utilize a spherical ball with a hole through the middle, which rotates within the valve body to either allow or block fluid flow. When the ball's hole aligns with the flow path, the valve is open; when rotated 90 degrees, it closes. This simple mechanism ensures a tight seal, making ball valves ideal for applications requiring quick shutoff and minimal leakage. They are widely used in various industries, including plumbing, oil and gas, chemical processing, and water treatment, due to their durability, corrosion resistance, and ability to handle high pressures and temperatures. Ball valves are particularly valued in systems where frequent operation and reliable shutoff are important, ensuring efficient and secure fluid control.

In conclusion, brass valves are a cornerstone of modern fluid control systems, underscoring their critical importance across a broad spectrum of applications. Their exceptional combination of strength, durability, and resistance to corrosion makes them highly reliable in managing the flow of various liquids and gasses, ensuring optimal performance and longevity in diverse environments. Brass valves, including lever, piston, gate, and ball types, each offer unique advantages that cater to specific needs within fluid handling systems. To review what we have discussed, lever valves provide straightforward, manual control, ideal for applications requiring frequent adjustments. Piston valves, with their precise flow regulation, excel in high-pressure and high-temperature environments, making them essential for demanding industrial applications. Gate valves are crucial for on/off control, providing a minimal pressure drop when fully open, which is particularly valuable in large-scale pipeline systems. Ball valves, known for their quick and reliable operation, deliver a tight seal and are highly effective for both shutoff and control purposes.

The versatility of brass valves extends beyond their mechanical functions; they contribute significantly to the efficiency and safety of fluid systems. By ensuring secure sealing, minimizing leakage, and facilitating smooth flow, brass valves play a pivotal role in preventing costly downtime and system failures. Their robustness and adaptability make them indispensable in various sectors, including plumbing, industrial manufacturing, water treatment, and energy production. As technology advances and demands for fluid control evolve, the enduring reliability and performance of brass valves will continue to be a fundamental asset, reinforcing their status as a critical component in maintaining the efficiency and safety of fluid management systems. Varco Supply carries a wide array of the types of brass valves mentioned above. Give us a call today at (866) 872-1224 or click here to shop brass valves.